Internal Shot Peening Machine for Steel bottle

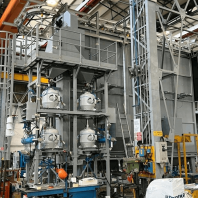

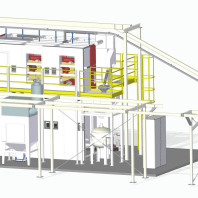

The shot peening machine is specifically designed for pre-treating the internal surfaces of steel bottle prior to coating application. As a highly efficient, fully automatic system, it performs internal abrasive blasting on small steel bottle, achieving consistent surface preparation. The equipment features automated loading and unloading, along with precise, hands-free shot blasting of steel bottle interiors—ensuring high productivity and process reliability.

The inner-wall shot peening machine for gas cylinders features two stations, each handling one cylinder. Cylinders are fed from a storage rack to an automatic loading position, where they are securely clamped. Once positioned in the spray chamber, custom-designed spray guns automatically extend into the cylinder and move vertically to thoroughly blast the entire inner surface—including the flange, bottom, side wall, and top—ensuring complete and uniform coverage.

Upon completion of sandblasting, the machine automatically shuts off the abrasive flow and uses the same system to blow residual media out of the cylinder. This integrated design allows full pre-treatment at a single station. Once the blasting assembly retracts, the cylinder automatically rolls to the unloading platform, completing one cycle.

The system features a closed-loop abrasive recycling unit that continuously recovers, cleans, and reuses high-quality media, while segregating worn or undersized particles into a central filtration unit.

Operated by a single user, the machine delivers maximum productivity and is equipped with an intelligent control panel for easy operation, monitoring, and maintenance.

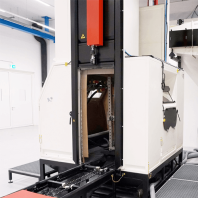

Customized curved nozzles

The inside surface of pipes is blasted using a custom-made lance movement blasting system. Abrasive stream covers the inside surface of pipes with the help of compressed air by using special designed types of nozzles.

Easy maintenance

Machine is self-diagnosing (troubleshoot pop-ups) and designed for fast service operation.

vacuum injection and pressure blasting.

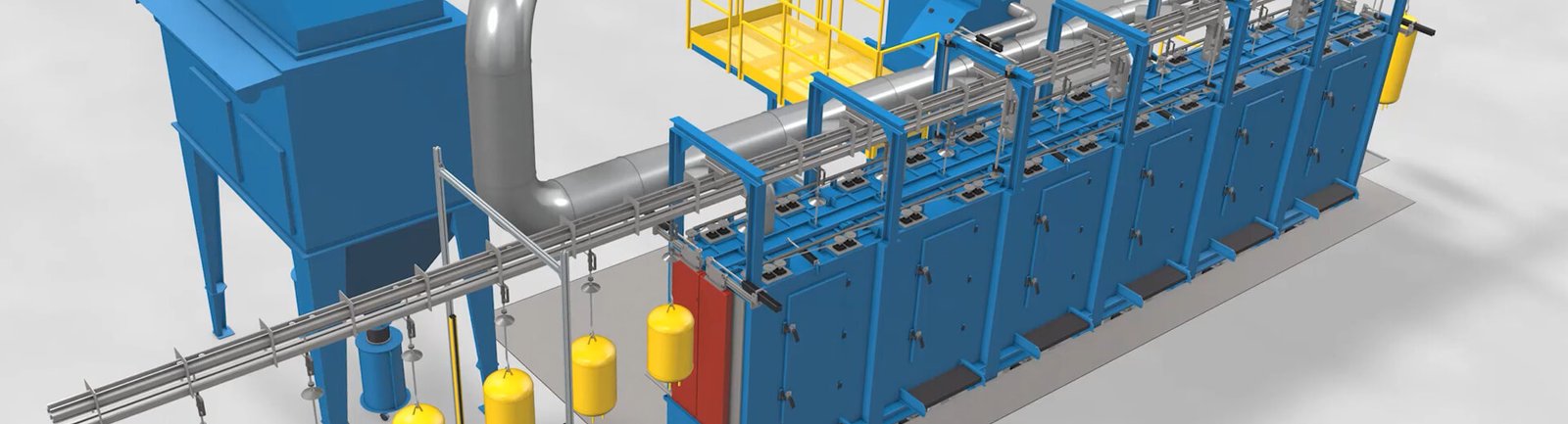

Double pressure vessel

Pneumatic driven reclaim unit

1 axis Servo driven nozzle manipulator

Machine Process Control Systems

Twin Media Reclaim System

Rotary Peening Head

Other references

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com