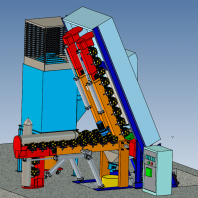

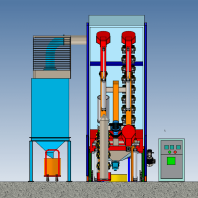

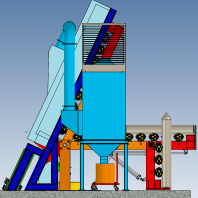

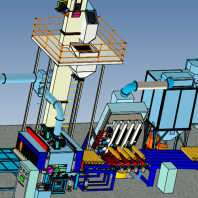

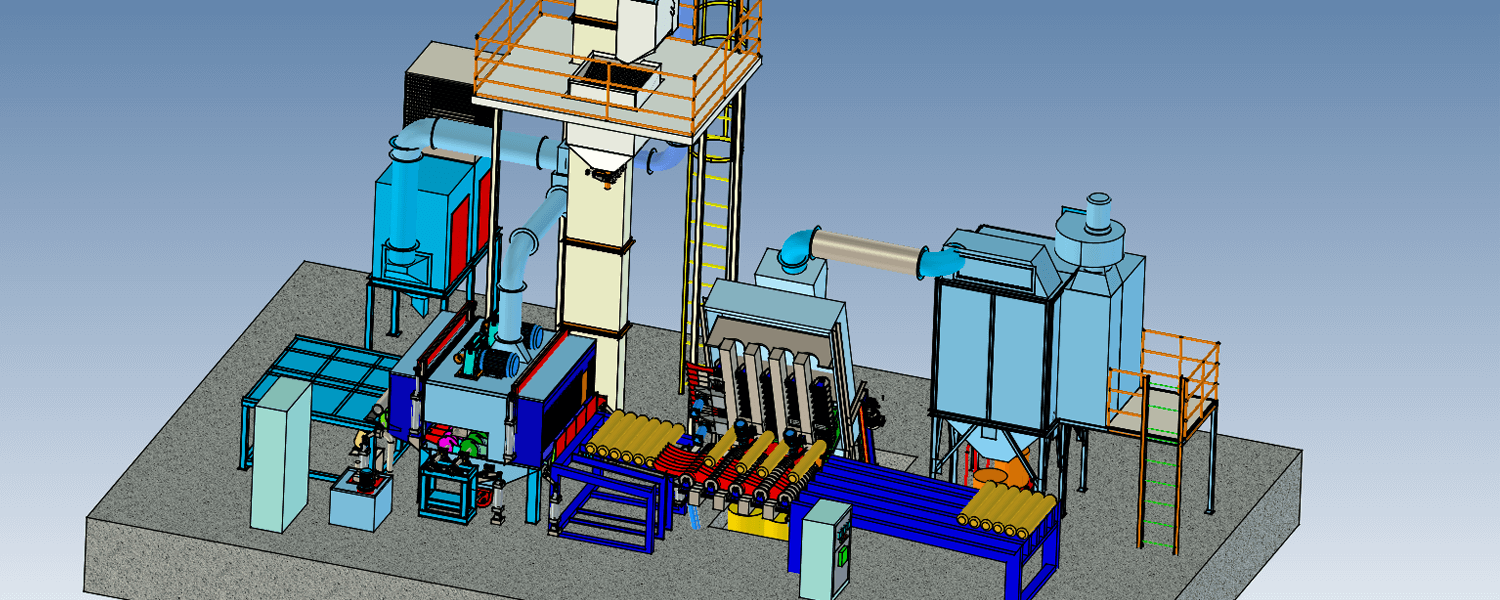

Small cylinder inner wall sandblasting machine

The cylinder inner wall sandblasting machine is designed for surface pre-treatment prior to coating application. DISA has developed a high-productivity, fully automatic system specifically for internal sandblasting of small cylinders. The equipment enables fully automated loading, unloading, and inner-wall blasting operations.

The small cylinder inner wall shot peening machine features two workstations, each processing one cylinder simultaneously. Cylinders are automatically transferred from a storage rack to the loading station, where a clamping unit securely holds the workpiece in place.

Once the cylinder positioned in the blast chamber, specially engineered spray guns automatically extend into the cylinder and perform a complete vertical stroke—from the opening flange through the side wall to the bottom and top covers—ensuring thorough and uniform coverage of the entire inner surface. Upon completion of blasting, the abrasive flow is automatically shut off, and the same system blows residual media out of the cylinder. This integrated design allows full pre-treatment within a single workstation. The blast assembly then retracts, and the cleaned cylinder rolls automatically to the unloading platform, completing the cycle. The machine is equipped with a closed-loop abrasive recovery and recycling system that continuously cleans and classifies the media. Only high-quality abrasives are returned to the blasting circuit, while degraded particles are directed to a central filtration unit for removal. Operated by a single technician, the system delivers maximum throughput and features an intelligent control panel for easy operation, monitoring, and maintenance.

Other references

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com