- View Products

- Blasting pots

- Blasting cabinets

- Suction blasting cabinets

- Injection blast cabinet type SKIF

- Pressure blasting cabinets

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Shot blasting room

- Big blasting halls

- Shot blasting container

- Automated shot peening machines

- shot blasting equipment

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

- Internal Pipe Shot Peening System

- Gas cylinder inside blasting machine

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

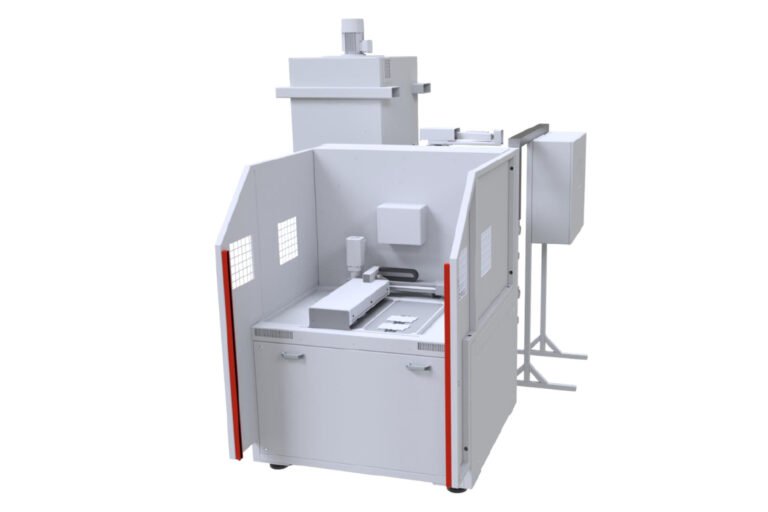

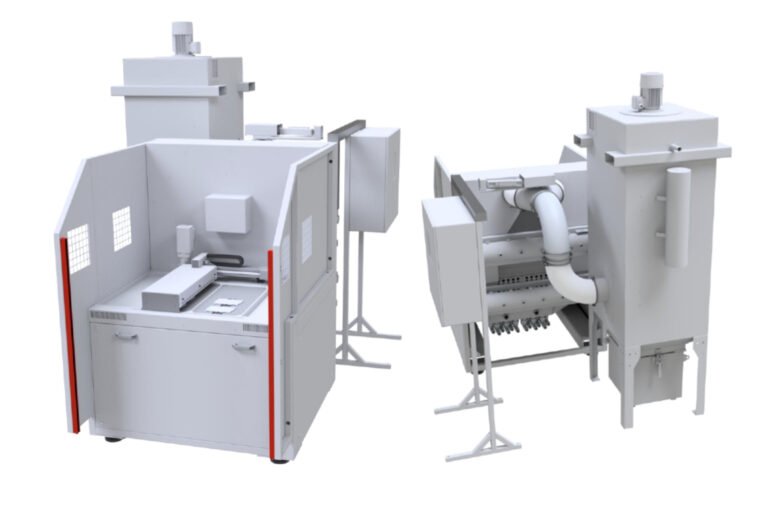

Internal hole & inner cylinder blasting machine

Whatever the size of the part to be processed, DISA’s sandblasting machines for cylinders and cylindrical bodies deliver high-quality finishes, essential for optimal preparation of parts for subsequent galvanic or paint processes.

DISA provides powerful and precise solutions for inner hole shot blasting of various industrial components to improve their fatigue resistance and overall service life.

Semi-automatic blastingmachine

With our proven track record in building automatic blasting machines, accumulated over decades, we work closely with our customers to provide the best possible solutions and to build long-lasting business relationships.

One of the customer requirements was a cycle time of maximum 12 seconds per two elements. We took on this challenge and successfully completed it.

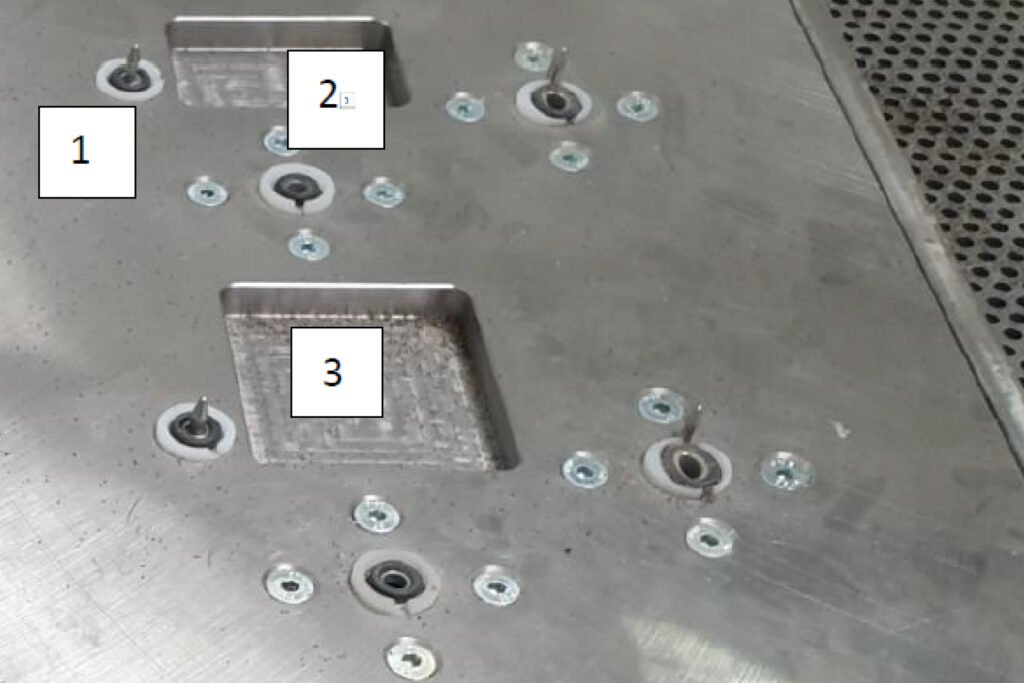

Shot peening of internal surfaces—such as holes, internal gears, internal splines, and pipes—requires specially designed nozzles tailored to the component’s geometry, hole diameter, and depth.

Achieving optimal results demands precise control of the impact angle and complete coverage of the target area. Verifying full coverage typically requires specialized optical inspection equipment.

Holes and pipes with diameters down to approximately 15 mm can be shot peened directly without costly tooling. For diameters below 15 mm, custom nozzles and dedicated devices are necessary.

When the diameter drops below approximately 8 mm, the holes generally must be through-holes (i.e., drilled completely through) to allow effective shot peening. Even bent pipes can be internally shot peened.

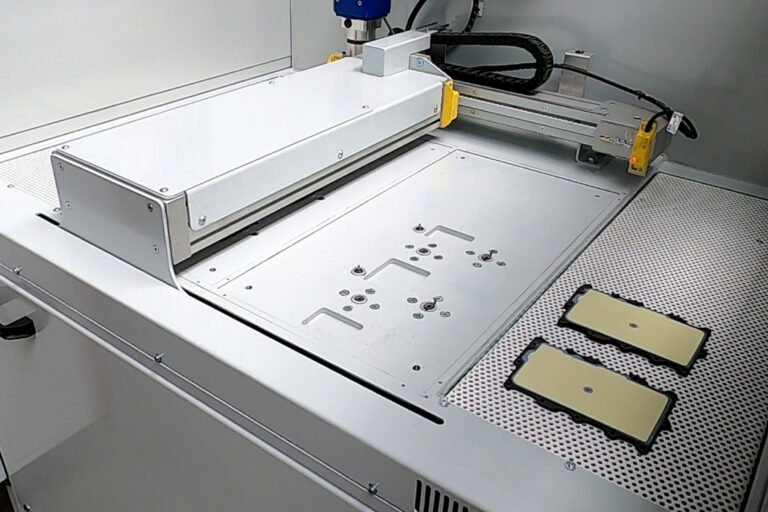

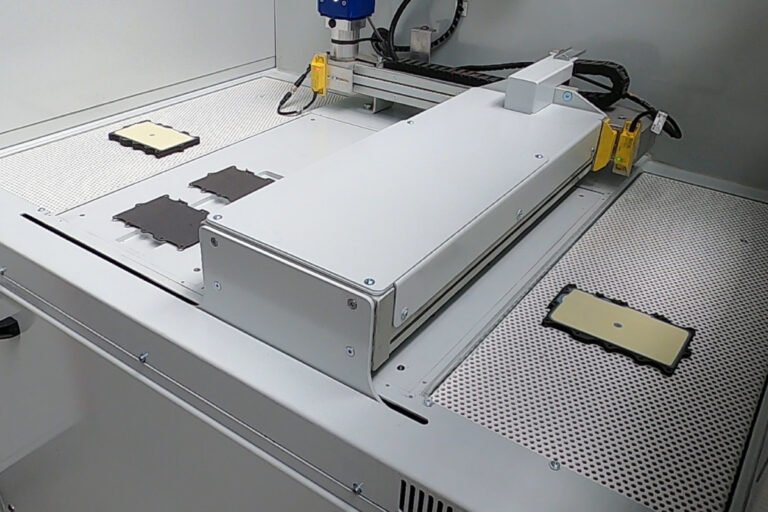

We use an electrically driven linear traverse guide with sled. This sled, which moves over the elements, presses the element against the masking plate when in position, after which the blasting process begins.

When two elements are being blasted on the right position, the operator can swap the blasted elements on the other side with two elements to be blasted. The downtime is therefore minimal.

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).