- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

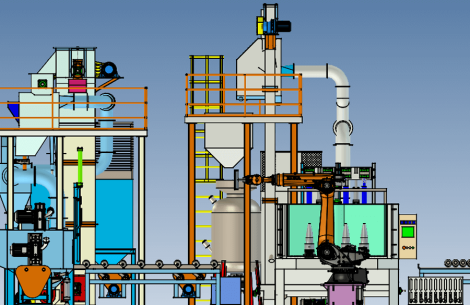

Inside surface shot peening machine

The bottle inner wall blasting system uses compressed air to accelerate abrasives to 60–120 m/s. A specially engineered 360° rotating spray gun generates a conical, diffused abrasive jet that uniformly impacts the entire inner surface, effectively removing rust, mill scale, and oil residues. The process achieves a surface cleanliness of Sa2.5–Sa3 and is ideal for both new cylinder manufacturing and periodic requalification of used cylinders.

During operation, the bottle is mounted on a rotating fixture (5–10 rpm) to ensure complete 360° coverage, while the spray gun automatically inserts itself and reciprocates vertically for consistent, uniform blasting. The system features a highly wear-resistant boron carbide nozzle for extended service life and is integrated into a fully automated PLC-controlled production line—handling feeding, precise positioning, sandblasting, and unloading seamlessly and efficiently.

Why choose Disa?

- Solid construction

- Shot peening of heavily stressed components

- Superior functionality

- Made in Holland

- Enhanced durability Excellent functionality

Inner wall shot peening machine for bottle

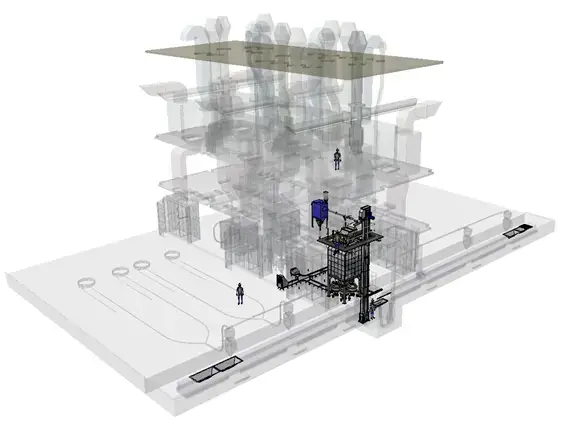

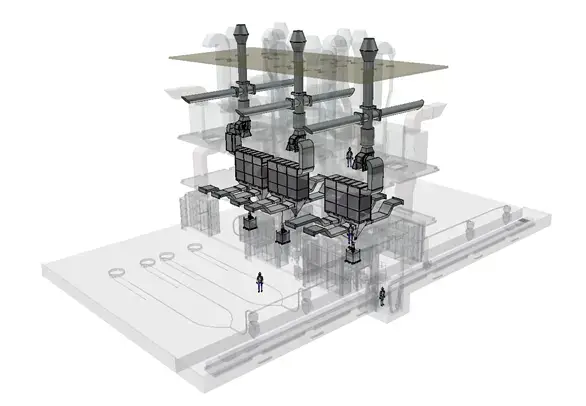

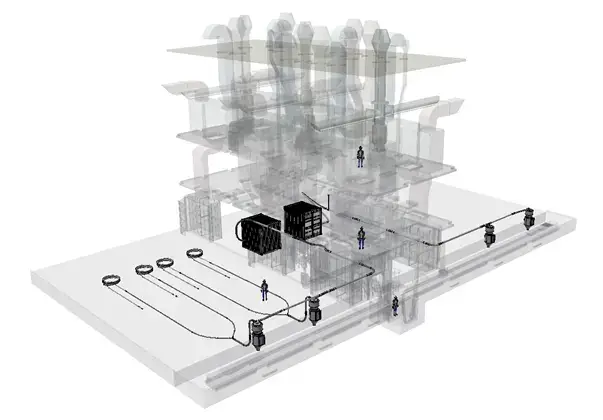

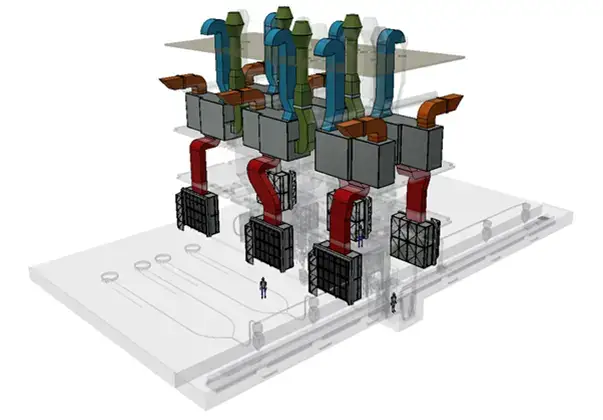

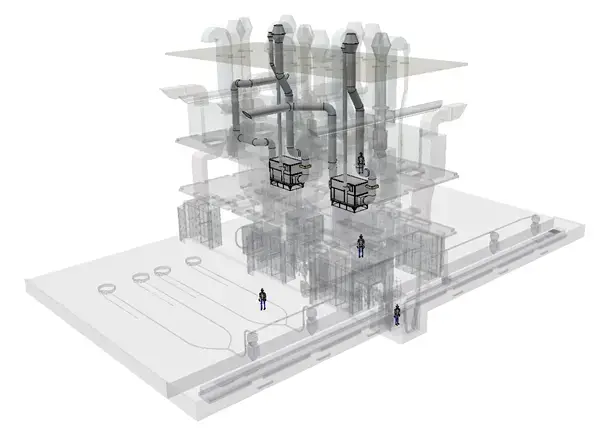

Large blasting halls: the components

Everything is big in this kind of large blasting halls. The abrasive media silo alone can hold up to 25 m3 of abrasive media, or up to 125,000 kg! Read on for more information.

The extraction system for large rooms is truly a giant. Straaltechniek International knows all about the installation of large filters up to 200,000 m3 per hour. Click on next for more information.

With the industrial vacuum suction system from Straaltechniek, the abrasive can also be easily and efficiently collected in these places.

Straaltechniek combines in this way the huge blasting hall with a very large painting workshop.

The humidity requirements are of course essential for the construction of the very large blasting room. Straaltechniek also provides these facilities for you.

The blasting hall: large, larger, largest

As you can see above: These large blasting halls have special features compared to the smaller blasting booths. As you can see above: These large blast rooms have special features compared to the smaller blast booths.The smaller sandblasting booth often has a screw on the back of the booth or a scraper all over the floor. This is no longer cost effective in the 8 meter wide beam hall. Therefore, conveyor belts are often used here under hoppers. This must be taken into account very carefully when laying the foundation stone. The transport of abrasives often has three times the capacity. For example 12 instead of 4 m3 per hour. The filters are much larger and the capacity here is often 100,000 m3 / hour. Since the room is also used as a paint workshop, there are also anti-fog paint walls with Andreae filters and temperature and humidity conditioning is provided. Large suction cups guide the abrasive towards the conveyor belts. Vacuum pumps are also protected against large amounts of dust. You can take a closer look at each module.

Do you have any questions? Call, WhatsApp or send us an email. For reference, you specify the word “blasting hall.”