- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@disamachinery.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Venti-floor Conveyor Recovery System Blast Room

The sweep-in recovery system sho blasting room adopts pure pneumatic drive, has no mechanical transmission components, and has low maintenance costs.

The sweep-in recovery shot blasting room is mainly composed of a room body, sandblasting equipment, abrasive recycling device, ventilation and dust removal device, abrasive sorting device, and electrical control device. To simplify the equipment, the abrasive recycling and ventilation and dust removal parts can be combined. The fan sucks all the abrasives, dust, and air flow into the abrasive centralized filter through the honeycomb floor. The dust-containing gas is filtered by the filter; the dust adheres to the outer wall of the filter, while part of the clean gas passes through the filter and is discharged outside the workshop, and another part is recycled into the sandblasting room. The abrasives and heavy dust continue to pass through the abrasive trough to the separator. The separator has an inner-outer cone structure, with an adjustable channel between the inner and outer cones. By adjusting the core body, the cross-section of the air flow channel can be changed, thereby adjusting the separation ratio. The separation process is as follows: when the abrasives and dust pass through the channel, due to the effect of gravity, the dust and gas go upward and come out through the gap between the cones, while the abrasives and coarse particles fall into the vibrating screen under the cones. The vibrating screen further separates the abrasives from the coarse particles. The separated pure abrasives enter the designated hopper through the sieve holes, then go to the sandblasting tank for recycling. The dust and gas passing through the separator are filtered again by another filter; the clean gas is discharged outside the workshop, and the dust falls into the waste hopper.

A sweep-in recovery system, with a high-efficiency dust collector, is an economical alternative to a full-floor recoverysystem.By cleaning and recycling the abrasive, a sweep-in recovery system saves material costs, compared to using expendable abrasives. And, with a sweep-in system you spend more time blasting, less time handling abrasives.

The blasting system adopts manual blasting. Special sandblasting pots are equipped for products of different materials. The pressure and flow rate of the sandblasting tanks can be adjusted at any time according to requirements. Each sandblasting tank is equipped with one spray gun, and the sandblasting system can allow 4 spray guns to work simultaneously.

The blasting room body is welded from steel plates, with its framework being a portal frame structure. The portal frames are connected by cross connecting rods and installed on the ground with anchor bolts through mounting blocks. Both sides of the portal frame are covered with pressed thin steel plates, which have a thickness of 0.5~0.8 mm and are painted on the surface. To improve the service life of the room body, 6mm thick wear-resistant rubber plates are pasted inside the room body.

The lighting uses a dust-proof lighting system, requiring that the indoor illuminance at 1 meter above the ground is not less than 650 lx. All doors leading to the sandblasting room are equipped with electrical interlocking devices to ensure that when any door is opened, the sandblasting system stops working. A warning light is installed outside the door, and the light being on indicates that sandblasting is in progress.

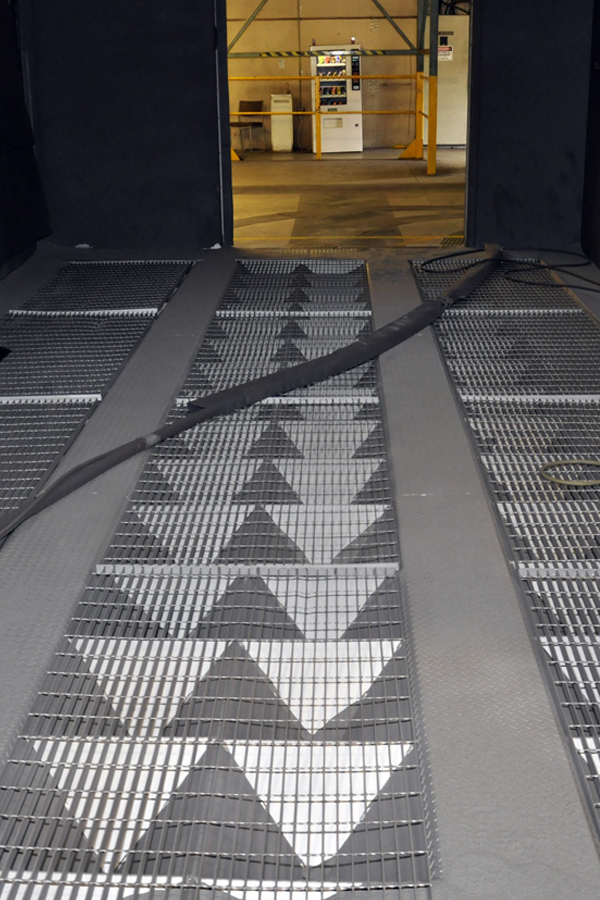

The viti-floor in the blasting room uses special honeycomb floors, each with a size of 500mm × 500mm. Along the length direction of the shot blasting room, every two rows of honeycomb floors form a honeycomb floor module. After the abrasive falls into the honeycomb floor, the fan sucks it through the material hole into the collection pipe, and then sucks it away from the collection pipe.

The abrasive collection and dust removal systems share a single set of equipment, including a central fan and a central filter. To ensure visibility inside the sandblasting room, the ventilation rate is set to no less than 50 air changes per hour, with three high-power fans in operation. The abrasive collector is designed with an upper and a lower layer; the lower layer serves as the abrasive passage, equipped with an air flow valve and a discharge port. When the air flow carrying abrasives, dust and impurities enters the collector, the air velocity decreases due to the enlarged cross-section, and the heavy abrasives and impurities fall into the abrasive trough through the discharge port. The lighter dust-laden gas is drawn away by the fan installed at the upper part of the collector.

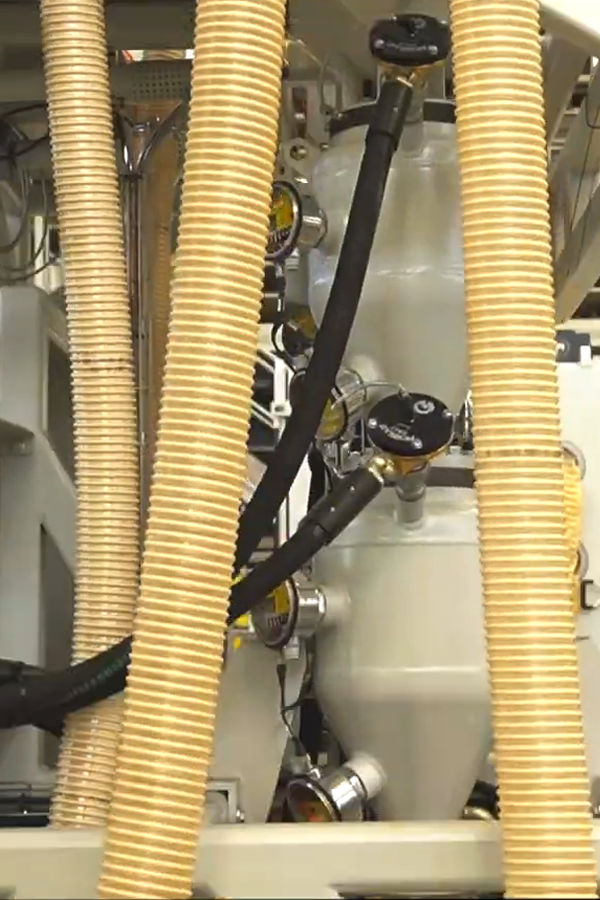

The abrasive recycling and sorting system includes an abrasive tank, a sorter, a filter, and connecting pipes. Abrasives are transported from the abrasive tank to the sorter through the connecting pipes, where they are sorted and recycled. To extend the service life of the sorter, wear-resistant rubber is pasted on the outside of its inner cone and the surface of its outer cone.

Due to the different materials of the products, the abrasives used for sandblasting also vary. To avoid the impact of iron abrasives on the workpieces, a set of magnetic separation devices is added under the separator to separate iron and non-iron abrasives, ensuring the quality of sandblasting. The magnetic separation device consists of a magnetic drum, under which a permanent magnet is installed. As the magnetic drum rotates, on the side where the magnet is located, the iron abrasives are adsorbed onto the magnetic drum due to the magnetic force. When the magnetic drum rotates to the side away from the magnet, the magnetic force disappears, and the iron abrasives fall into a corresponding container. The continuous rotation of the magnetic drum enables the separation of iron and non-iron abrasives in the abrasives.

For the convenience of work, electric workbenches capable of three-dimensional movement are installed on both side walls of the sandblasting room. The workbench has a length of 1.5 meters, a width of 0.6 meters, and a load capacity of 250 kilograms. The travel range is: 28 meters in the longitudinal horizontal direction, 1 meter in the transverse horizontal direction, and 3.6 meters in the vertical direction. A control station is installed on the workbench to control the main disconnect switch, the movement of the workbench, and the emergency stop

View these real-life examples

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).

The heart of the abrasive reclaim system removes contaminants from the abrasive mix,and the air-wash classifies the abrasive to maintain a constant size.This classifier can classify alltypes of dry ferrous and non- ferrous abrasives.

Constructed of mild steeel with angle iron

reinforcements.Malleable iron buckets bolted to a

heavy-duty(1/2″thick)belt convey the abrasive material

to the air-wash separator.

Free-standing hopper reinforced with structural steel. Positions above the blast tank assemblies to provide easy access for maintenance.