- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@disamachinery.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

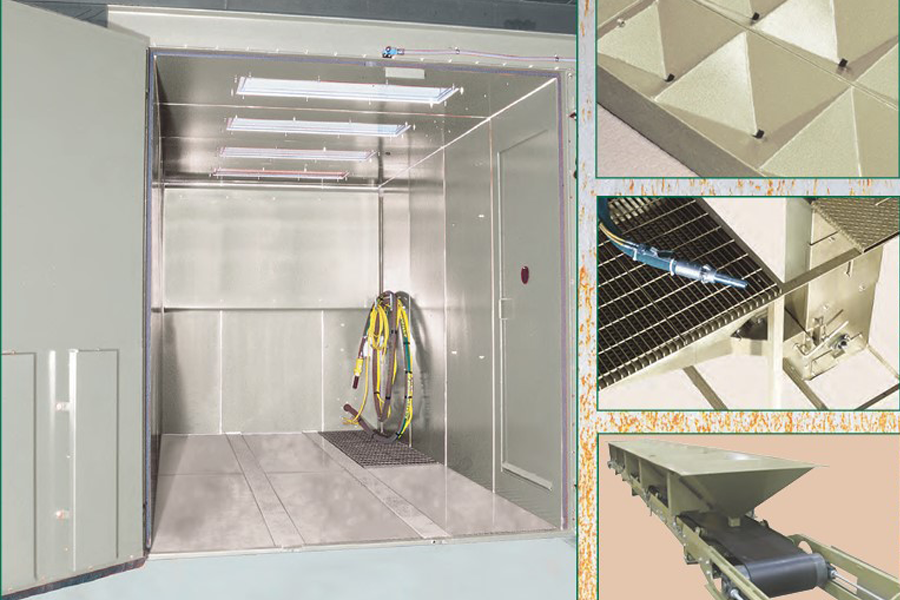

Shot blast container

This is a modular, high-performance compact blast & recovery blast container with the following features and advantages:

Space-saving design: Ideal for fitting into standard shipping containers and HI-CUBE shipping containers, and perfectly suited for limited blast workplaces.

Efficient abrasive handling: Equipped with a continuous abrasive feed system; supports standard connection to a loading hopper or floor transport of abrasive media, ensuring a smooth and uninterrupted blast & recovery process.

High-performance configuration: Built with a large-volume, highly efficient abrasive blaster; as a premium model, it is ideal for demanding industrial operations requiring high productivity and work effectiveness, and can be operated by two personnel simultaneously.

Custom buildshipping container sandblasting room

- Reduce the space given over to an installation

- Put in place efficient lighting

- Utilize comfortable personal protection equipment

- Increase the performance of the blaster

- Use energy more efficiently

- Reduce operating losses

- Collect dust more efficiently

- Wall & door trim – black rubber

- Comfortable control of blast operation directly from the workplace

- Elevator with minimal wear and tear

- Adaptable abrasive reclaim system

The working mode of this container-type shot blasting cleaning room is to place the workpieces inside the container, and the operators enter the container or insert their hands into it to clean the workpieces.

Brief Introduction:

Depending on the type of work to be performed, the container-type sandblasting room is equipped with an exhaust system or an overpressure system. It is fitted with an abrasive recovery and screening device, as well as filters for removing dust inside the room, thereby ensuring that operators always work in a healthy environment and are protected from injury caused by abrasive blasting.

For extremely heavy workpieces, the container can be equipped with loading and unloading components, screw conveyors and movable grating.

After placing the workpieces into the sandblasting room, operators wearing appropriate protective equipment enter the room to perform sandblasting on the workpieces. The room is equipped with exhaust equipment and abrasive recovery equipment to facilitate the cleaning and recycling of abrasives.

Its inner walls are made of wear-resistant materials, and the internal lighting is excellent, allowing work to be carried out easily and conveniently. The room is constructed with easy-to-assemble modular panels. Multiple configurations are available for the entry and exit of workpieces, which can be handled by conveyors, pneumatic rotary tables, or directly operated on the ground.

A variety of systems are adopted for abrasive collection, including the use of tractors, and no civil engineering work is required.

The container-type sandblasting room can be equipped with a special vibrating screen in the dynamic separator to prevent nozzle clogging and reduce maintenance work.

Example custom made blast container 2

This blast room has been custom built for blasting with glass beads. We’ve installed a Ventifloor system for the smart reclaim of abrasives.

| Technical details | |

|---|---|

| Type | 20/E20 |

| Size (LxWxH) | 6000 x 2440 x 2580 mm |

| Weight (empty) | +/- 5250 kg |

| Air usage | 6000 liter/min. at 7 bar |

| Nozzle | 8.0 mm |

| Connection | 7.5 kW – 7.8 kVA |

| Electricity | 380V – 3ph – 50 Hz |