- View Products

- Blasting pots

- Blasting cabinets

- Suction blasting cabinets

- Injection blast cabinet type SKIF

- Pressure blasting cabinets

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Shot blasting room

- Big blasting halls

- Shot blasting container

- Automated shot peening machines

- shot blasting equipment

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

- Internal Pipe Shot Peening System

- Gas cylinder inside blasting machine

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

DISA BLAST WHEEL for faster cleaning cycles

Straaltechniek International, known for its constant innovative developments in the field of blasting technology, has significantly advanced the development of blast wheel technology.

DISA blast wheels feature cast manganese wheel housings equipped with long-life premium alloy cast liners for extended wear resistance. The mill conveyor utilizes heat-treated cast chain links and hardened steel link pins for durability. The cabinet includes 1”-thick manganese barrel head liners and replaceable manganese liners throughout, ensuring long service life. A roller chain-operated work door is driven by a shaft-mounted gear motor with an integrated brake and safety lock for reliable and secure operation.

Why choose Disa?

- special C-shape of the blades

- completely new blade holder (patent BE2012 / 0244)

- improved abrasive flow

- Own service department

- Delivery options from stock

- Over 30 years of experience in the blasting technique

- up to 70% higher blasting efficiency

- 10 times longer life expectancy of the blades

- 3 times longer service life of the blast wheel – side windows

- extremely suitable for blasting with angular steel abrasives

- completely customer-specific, but also standard blasting system solutions

- suitable for many types of objects

- strictest quality requirements

- High-end wheel blasting systems

- optimal cleaning of the abrasive

- Dust emissions below 3mg / m3

- Control cabinet with PLC control

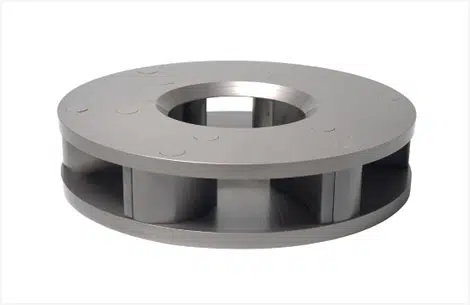

Disa blast wheels

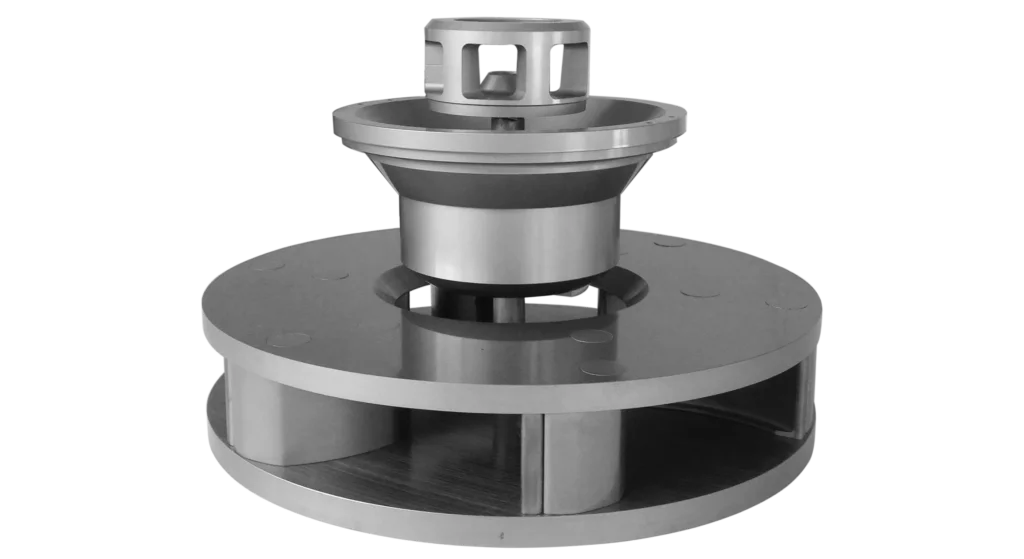

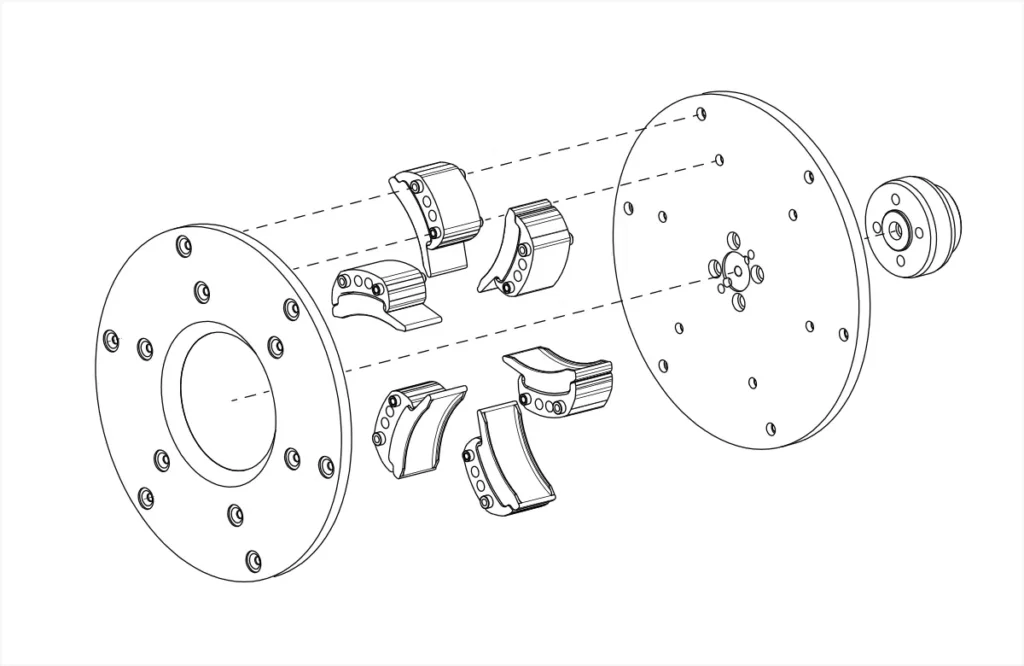

Revolutionary throwing blades holder

The blast wheel assembly is the heart of every DISA machine, engineered for peak performance and durability. Each wheel features premium cast blades precisely balanced—blade sets are weighed before leaving the factory to enhance wheel balance and extend service life. During operation, a controlled flow of abrasive continuously enters the rotating impeller via the feed spout, synchronized with the blast wheel. The abrasive accelerates within the impeller and is smoothly directed onto the individual blades through a slot in the control cage. By rotating the control cage, the slot position can be adjusted to precisely control the direction of the blast stream and easily set the “hot spot” for optimal impact. An ammeter monitors the actual abrasive flow in real time.

Direct-drive blast wheels ensure maximum energy efficiency at all times. The blades are uniquely curved in the direction of rotation to deliver high velocity, uniform distribution, and superior blast pattern control. Thanks to the innovative snap-lock blade design, worn blades can be quickly and easily replaced without specialized tools. The entire wheel housing is fully lined with interlocking, cast wear-resistant liners for maximum protection, while an adjustable abrasive valve enables precise regulation of media flow—ensuring consistent, efficient, and reliable blasting performance.

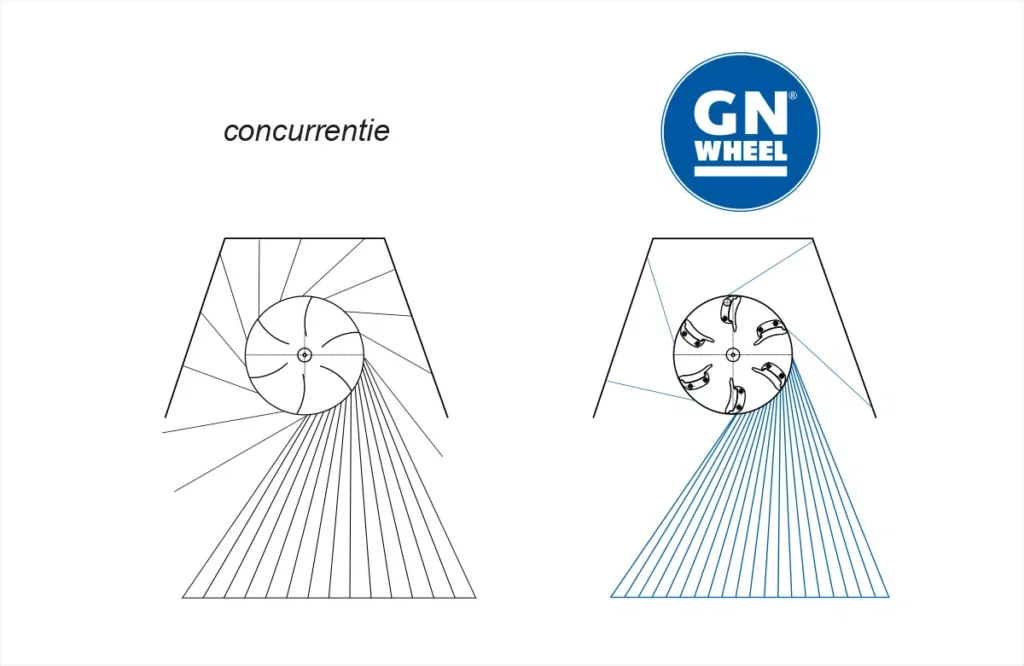

High efficiency and optimization of the abrasive flow

The symmetrical sandwich construction (double side panes) of the GN Wheel® ensures an efficient and even flow of blasting media within the blast wheel. Conventional blasting wheels lose power due to the turbulence of the abrasive inside the turbine. The revolutionary throwing blade mount of the GN wheel ®, which at the same time takes on the task of connecting webs, avoids these performance-reducing blasting media turbulence. The innovative design of the GN Wheel® guarantees a 7 times better flow of blasting media, 5% higher energy efficiency and 3 times longer service life of the side windows compared to all other turbines available on the market.

The blasting wheel workings

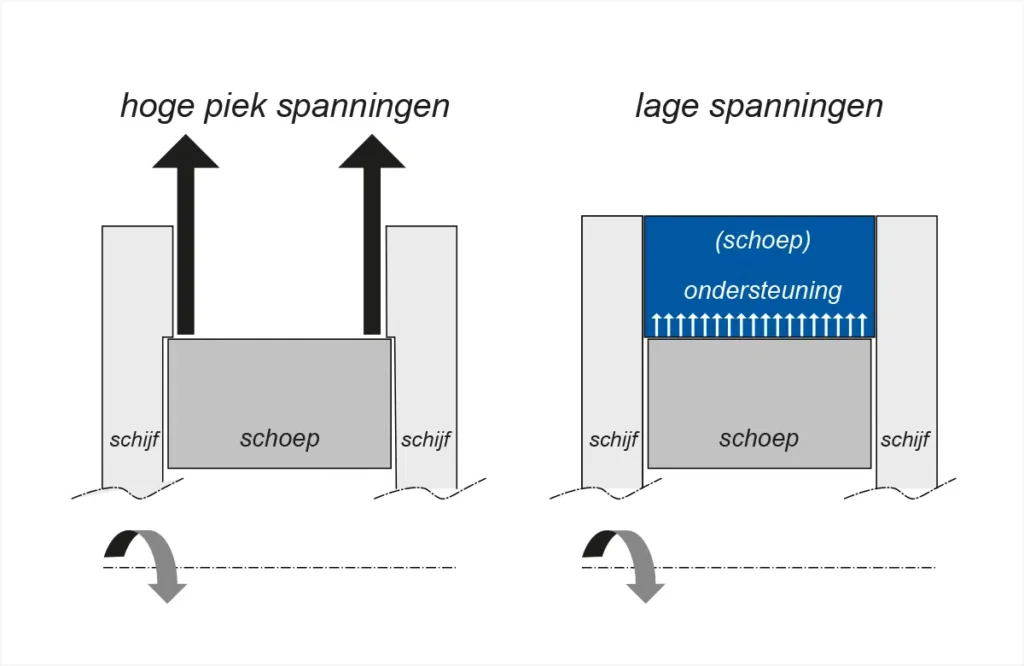

Special C-shape of the blades

Straaltechniek International has further developed the principle of the C-throwing blades under the aspect of minimizing stress factors and this leads to the revolutionary concept of the unit of throwing blade and throwing blade holder. Thanks to the precise knowledge of the kinematics and the blade receiving units developed from it, the impact energy at the entrance of the blasting agent to the throwing blade is massively minimized, so that the throwing blade and blasting agent are less stressed. A curvature of the throwing blades adapted to the trajectory parabola enables a 25% higher exit speed of the abrasive, which results in a significantly lower consumption of abrasive. The performance of the GN Wheel® is up to 70% higher than that of conventional blasting wheels.

Extremely easy to maintain

When developing the GN Wheel®, Straaltechniek International also attached great importance to ease of maintenance in order to keep the costs for downtime and assembly particularly low for the operator.

Delivery program

The GN Wheel® is available in diameters of 300 – 506 mm and can be used on all existing and future blast wheel machines. The GN Wheel® has proven its effectiveness under the toughest operating conditions, e.g. when using angular blasting media type GH with a hardness> 64 HRC and can be optimally retrofitted regardless of the blasting system manufacturer.

Blast wheel retrofitting

Retrofitting of the existing blower wheel systems with the new GN wheel® is possible without any problems. Please turn to our staff in confidence.