- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

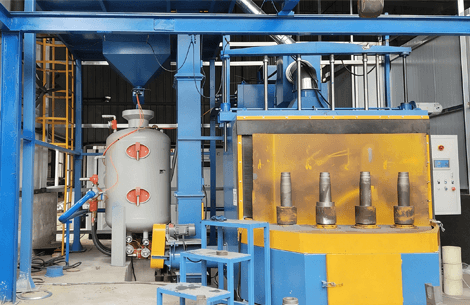

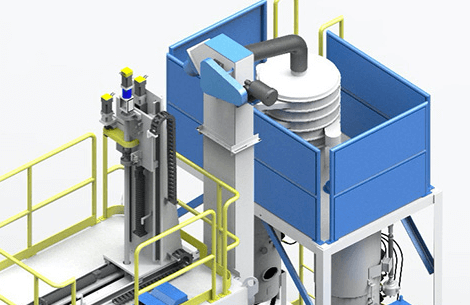

Inside surface shot peening machine

The bottle inner wall blasting system uses compressed air to accelerate abrasives to 60–120 m/s. A specially engineered 360° rotating spray gun generates a conical, diffused abrasive jet that uniformly impacts the entire inner surface, effectively removing rust, mill scale, and oil residues. The process achieves a surface cleanliness of Sa2.5–Sa3 and is ideal for both new cylinder manufacturing and periodic requalification of used cylinders.

During operation, the bottle is mounted on a rotating fixture (5–10 rpm) to ensure complete 360° coverage, while the spray gun automatically inserts itself and reciprocates vertically for consistent, uniform blasting. The system features a highly wear-resistant boron carbide nozzle for extended service life and is integrated into a fully automated PLC-controlled production line—handling feeding, precise positioning, sandblasting, and unloading seamlessly and efficiently.

Why choose Disa?

- Solid construction

- Shot peening of heavily stressed components

- Superior functionality

- Made in Holland

- Enhanced durability Excellent functionality

Inner wall shot peening machine for bottle

Operating principle and structural features:

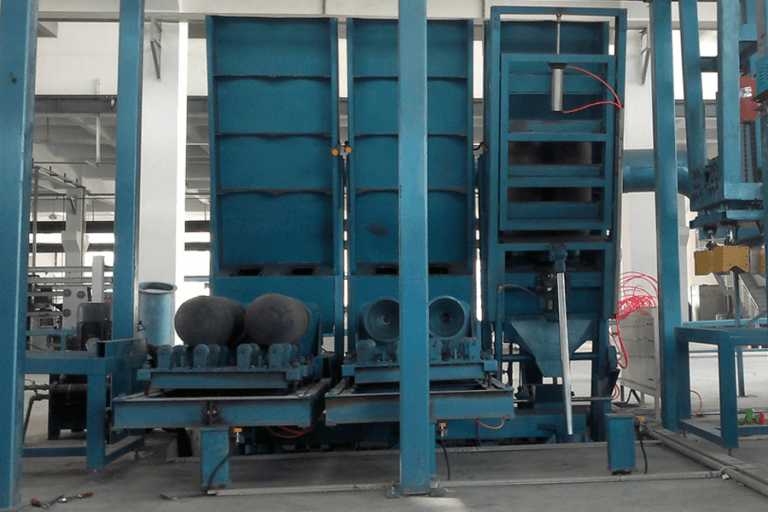

Put workpiece on the loading rack horizontally, feeding cylinder works and holds up the workpiece, then advancing cylinder carries it to the rolling-over rack and then fell back to the original position. Meanwhile, rolling-over cylinder locates the workpiece at a certain angle so as to consistent with the chamber enclose.

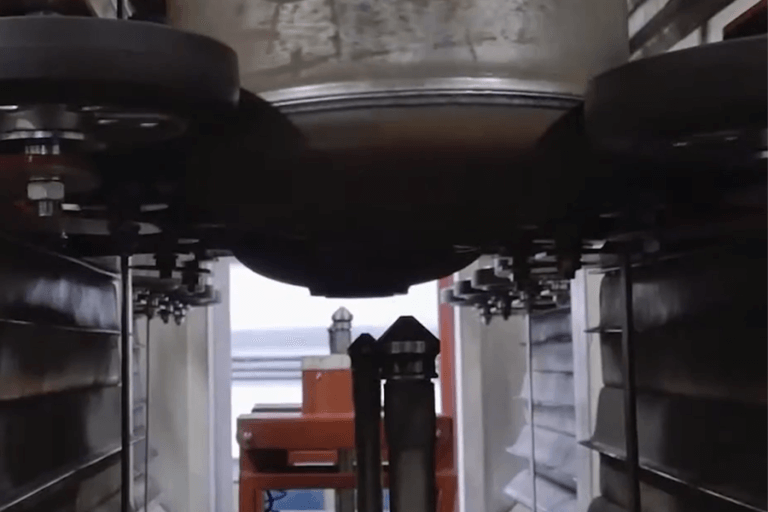

Spray gun that is driven by the mobile device moves into the inside of steel bottle along the orbit horizontally. At the same time, the gun works and so the cylinder rotation device, so the bottle begins revolving. After moving and spouting shots inside the cylinder, the gun then gives a high-pressure gas to remove the inward shots and dust. The gun goes out and stops work.

After rolling-over cylinder flips the steel cylinder into a level state, unloading cylinder holds the workpiece up.Then advancing cylinder pushes it to the unloading position and discharges it. The dust of the entire work process is adsorbed by the dedusting system and falls so as to meet requirements of environmental protection.

Gas cylinder Inside surface shot peening machine: the components

The cylinder inner wall shot blasting cleaning machine integrates key components including: a pneumatic flip-type sealed chamber (front and rear), a blast gun with guiding mechanism, a blast gun carrier equipped with a variable-frequency speed-regulated travel system, a cylinder rotation and clamping system, an automatic loading/unloading unit, a wind-powered abrasive recycling system, a sand hopper, blasting pot, air separator, dust collector, pneumatic and compressed air systems, and an electrical control system.

Blasting guns and pots are installed in the chamber, which features front/rear sealed chambers and multi-layer protection to prevent abrasive and dust leakage; its inner walls are lined with high-manganese steel plates for impact resistance.

The cylinder is V-supported by 2–4 sets of wear-resistant rollers; driven by friction from active rollers, with horizontal adjustment for varying diameters.

The clamping system secures both ends of the steel cylinder, and the rotating system spins it at a constant speed. Simultaneously, the sandblasting gun enters the cylinder and cleans the inner wall along a preset path—combining circular and axial motion. Once complete, rotation stops, the clamp releases, and the cylinder is conveyed out.

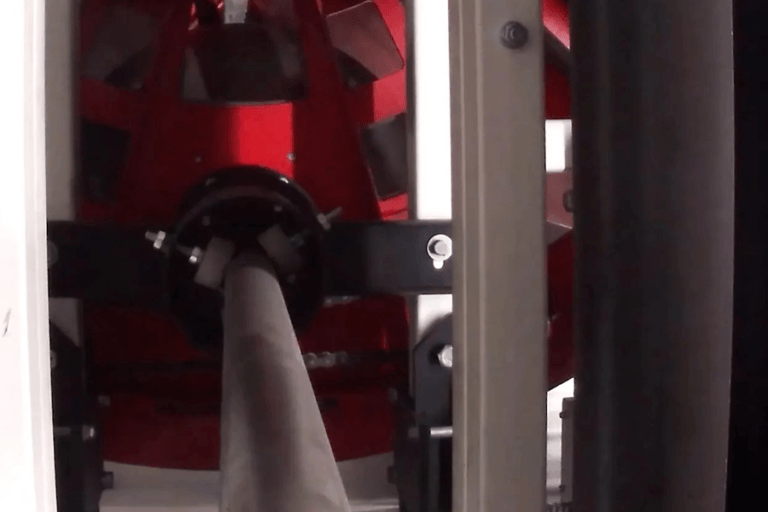

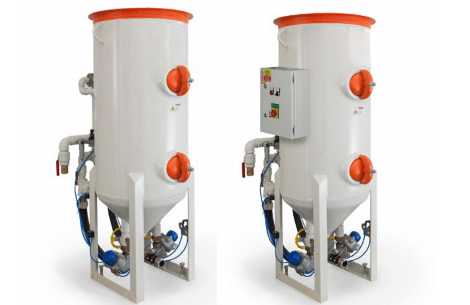

The Abrasive Recycling Systems are an abrasives cleaning, recycling and separation system, designed for use with blast pot.The Abrasive Recycling Systems are an abrasives cleaning, recycling and separation system, Cleaning of abrasives is vital during operations to ensure maximum abrasive blasting productivity. With less dust and fines in the abrasive, not only is the blasting process more effective, but there will also be less airborne dust released into the environment, and less wear and tear on the blast pot and associated components.

This CE-certified double-chamber continuous blasting features a mushroom valve (auto-sealing on air inlet), inlet/exhaust valves, a sand regulating valve, and a level sensor—enabling uninterrupted operation through alternating chamber feed, with reliable sealing, precise flow control, and safe performance.

This dust collector is made of 3mm steel plates, featuring a sturdy and durable structure, a compact overall design, and space-saving for installation. Equipped with the Jet Plus dust cleaning system, it ensures efficient cleaning while significantly reducing compressed air consumption.

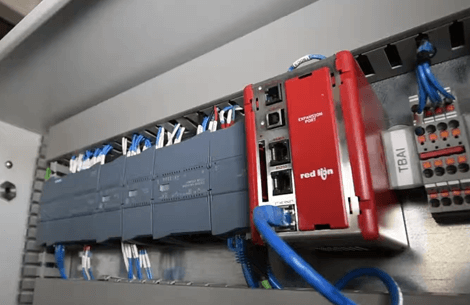

The electrical control system is configured for the power distribution of three-phase AC with a frequency of 50 Hz and a voltage of 380 V.Electric interlock and self-locking mechanisms are fitted to the blasting gun, maintenance door, abrasive controller and abrasive circulation system, ensuring reliable equipment operation and operator safety.

Cylinder Inner Surface Shot peening Equipment

In cylinder manufacturing and reconditioning, internal sandblasting serves two primary purposes: preparing a clean, uniformly roughened surface that meets SA 2½ or SA 3 standards for subsequent coating, or stripping failed or damaged coatings from used cylinders during refurbishment. To address diverse production requirements, DISA offers a comprehensive range of internal sandblasting solutions: Rotary internal sandblasters for high-volume production, Suspended systems that integrate seamlessly with coating lines, Single-station units ideal for low-volume operations, As well as dual- and four-station configurations that combine efficiency with flexibility—effectively supporting applications ranging from small-batch processing to large-scale continuous production.

Do you have any questions? Call, WhatsApp or send us an email. For reference, you specify the word “cylinder blasting.”