- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@disamachinery.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

Scraper floor Reclaim System Blast Room

We design scraper floor Reclaim System Blast Rooms for long life, for highest productivity,for operator ease both in use and maintenance.

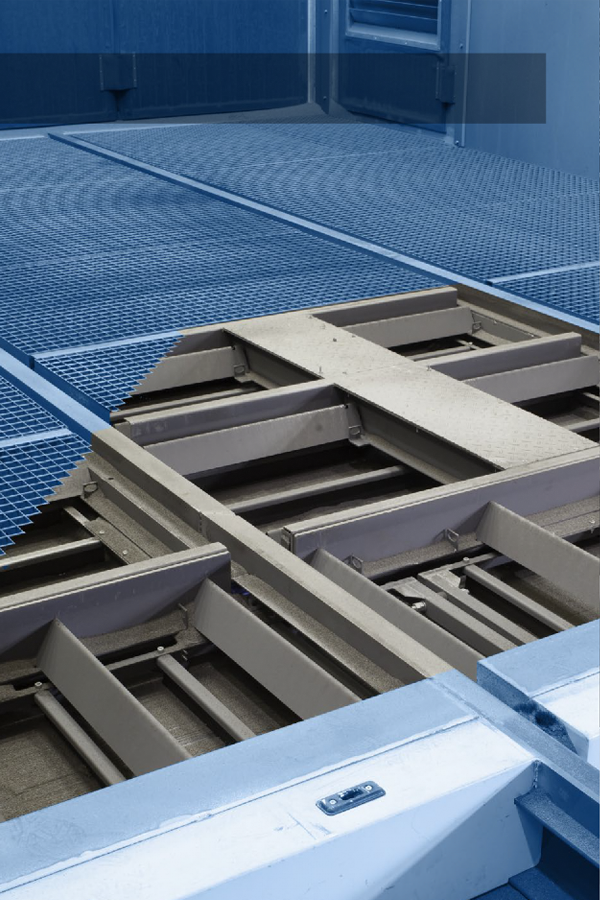

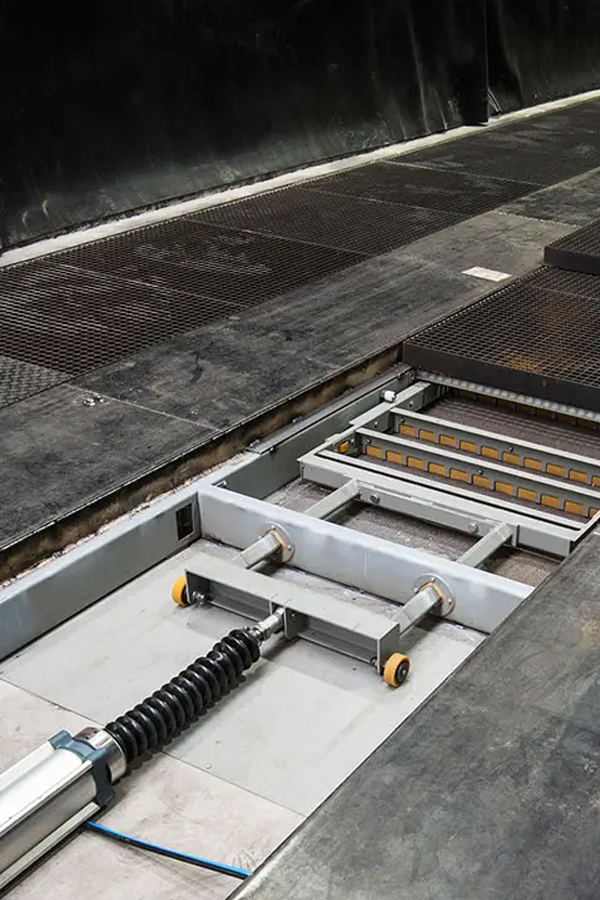

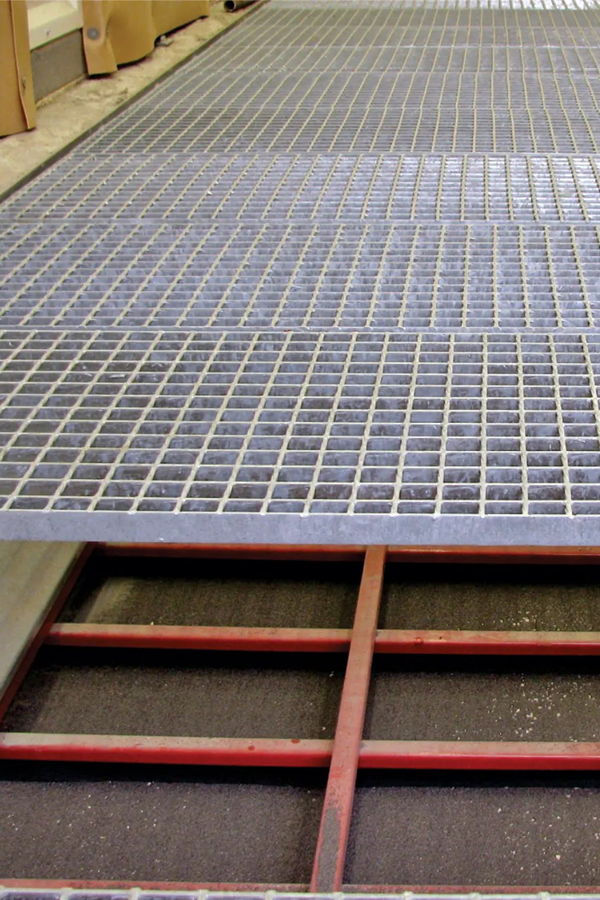

Utilizes multiple screw assemblies to create a fully automatic abrasive reclaim system , where 100% of the blast media is resumed to the separator system during the blasting operation, the full floor reclaim design requires that the material handling of the work piece be intricately designed into the configuration of the room material handling of the work piece includes a work car track system an overhead monorail crane an overhead bridge crane or heavy – duty for grating and support steal sized to allow a forklift to drive onto the reclaim for this design can be used with any room configuration and is best.

The most economical for design available . the system contains metering shed plates . heavy duty screw belt and bucket elevator . 20” air wash separator , perforated plate rotary drum separator and oversized abrasive storage hopper with a caged man ladder and handrail. this can be expanded to an H U or full for reclaim system and is best suited for low to medium product on levels.

Adds two longitudinal metered screw assemblies along each side wall of the blast room allowing the abrasive deleted from the blasting nozzle which is either blown or rebounded off the work piece to strike the side walls and fall into the screws automatically reclaiming approximately 60-90 percent of the blast media. the remaining abrasive on the floor is pushed into the metered shed plate screw assemblies at the end of the work shift. The H shape floor design is typically used in a flow – through room configuration where heavy work pieces and or material handling devices can drive into the room This is best suited for medium to high production.

Adds two longitudinal metered screw assembles along each wall of the blast room and positions the cross screw along the back wall of the blast room this allows the abrasive delivered from the blasting nozzle which is either blown of rebounded of the work piece to strike the side walls and back wall of the blast room and fall into the reclaim system a u-shaped floor design will automatically reclaim 50-90 percent of the blast media the remaining abrasives on the moor is pushed into the metered shed plate screw assembles at the end of the work shift ,the u shaped for design is typically used in an in-out room configuration where heavy work pieces and or material handling devices can drive into the room this is best suited for medium to high production.

View these real-life examples

More information?

Ask our advisers your questions by telephone, WhatsApp or via email (button below).

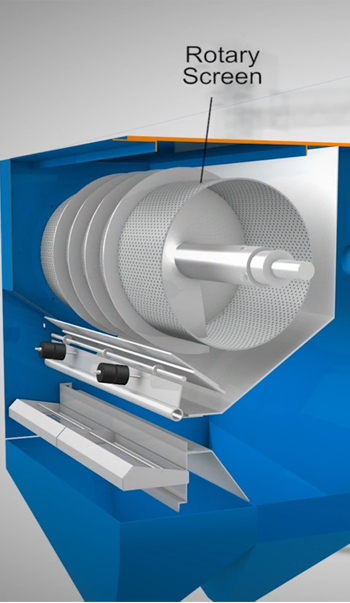

The heart of the abrasive reclaim system removes contaminants from the abrasive mix,and the air-wash classifies the abrasive to maintain a constant size.This classifier can classify alltypes of dry ferrous and non- ferrous abrasives.

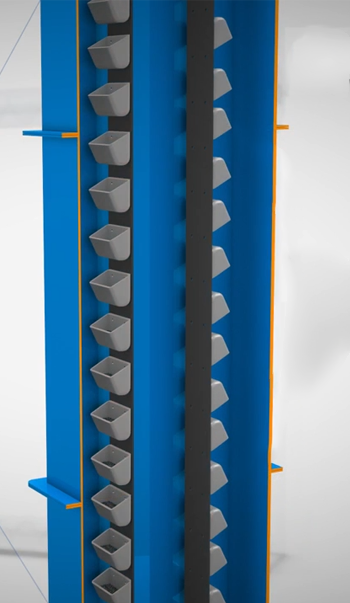

Constructed of mild steeel with angle iron

reinforcements.Malleable iron buckets bolted to a

heavy-duty(1/2″thick)belt convey the abrasive material

to the air-wash separator.

Free-standing hopper reinforced with structural steel. Positions above the blast tank assemblies to provide easy access for maintenance.

Heavy-duty screws return the abrasive to the separator/classification system.Stanrd screws are 9″in diameter which consists of a 5″diameter schedule 40 pipe wrapped with 1/4″thick fighting on a 2/3 pitch.