- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@disamachinery.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

The floor of cabin:

All abrasive recovery system include three basic functions: Delivering the abrasive which rebounds off the workpiece too a central recovery point. Transporting the abrasive from that central point to an abrasive cleaner. Removing dust, fines and other unwanted material from the abrasive before it enters the blast machine to re-use.

Smart reclaim of abrasive:

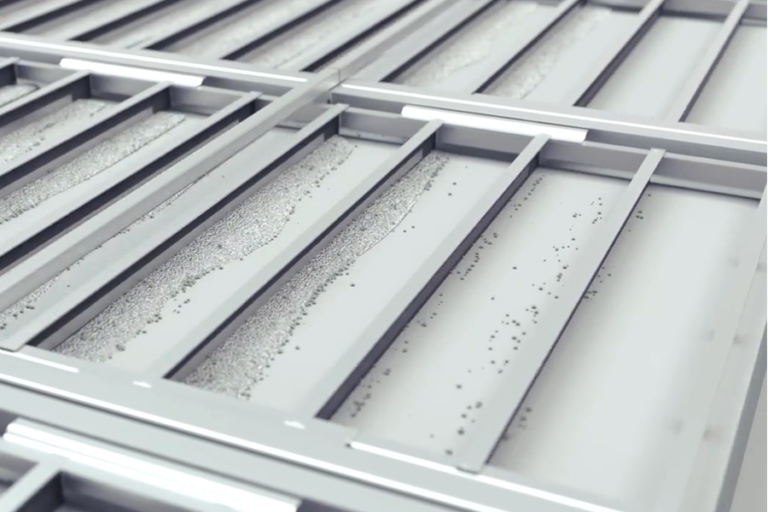

Scraper floor Reclaim System

This system combines the drive of scraper carts that conduct the abrasive material to the rear of the working chamber,The long scraper tracks are equipped with rubber scraper flaps, which push the abrasive in the direction of the cross conveyance. where it is collected by a screw conveyor which conducts the abrasive material up to the foot of the bucket elevator (abrasive materials purifier). On the whole floor surface, there is a grid that is covered with a perforated plate, which retains larger impurities or even small parts which may drop accidentally on the floor.

Single-layer or multi-level placement of longitudinal or lateral rake conveyors. Stor- age of collected abrasive without the need for building foundations. Cost-effective connection of longitudinal rake conveyors. Direct-drive transmission between lon- gitudinaland lateral rake conveyors. A reclaim system around the entire perimeter. A fluctuating width of rake conveyors.

advantages:

- Shallow foundation

- Reduce Abrasive Costs

- Polyurethane scraper: tough and durable

Screw conveyor recovery system

Our Blast Rooms can be supplied with a sweep up recovery system where the abrasive has to be manually swept into a hopper for recycling or we can

supply a series of screw conveyors to give a partial or full recovery system. With a partial recovery system the some of the abrasive has to be swept into the screws conveyors manually and with a full recovery system the recover of the abrasive is fully automated.

All our screw conveyors are fitted with a “shedder” that stops the screw conveyors from getting blocked and also controls the flow of abrasive to the screw to avoid over loading due to surges in abrasive during operation and the clean down of the product being processed.

All our screw conveyors have a mild steel hopper that is installed in the foundation, fitted in this is the screw conveyor mounted on heavy duty self aligning bearings. The bearings are sealed from the ingress of abrasive for long life, long screw conveyors have a hanger bearing mounted every six metres for support.

The screw conveyor flight is made from 6mm thick steel welded to a seamless pipe. Each screw conveyor flight is supplied in a length equal to its diameter so replacement of a small section when wear occurs is very easy.

The shedder fitted above the screw conveyor stops any large items from entering the screw conveyor and controls the flow of abrasive via the precise gap thus avoiding any over loading of the screw.

The drive for the screw conveyor is by a helical type geared motor.

advantages:

- Stable transportation and high efficiency

- Easy to maintain and reliable in operation

- It forms a complete abrasive recycling system together with bucket elevators, separators, etc., enabling automated recycling and reuse.

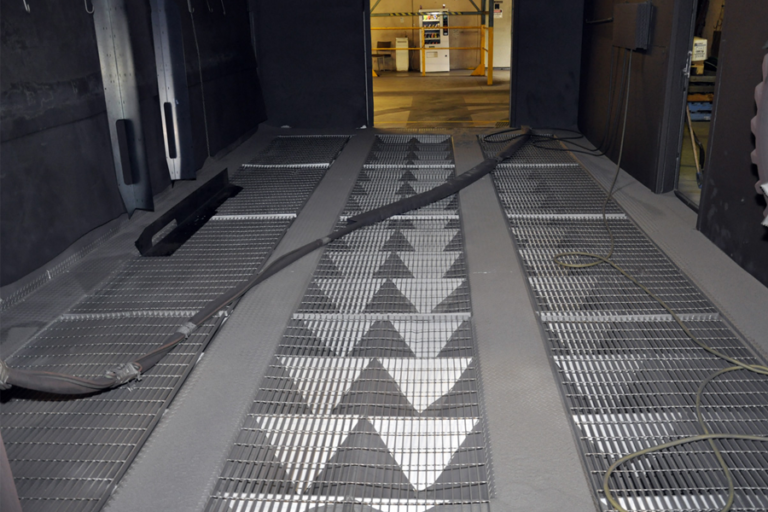

Venti-floor conveyor recovery system

The venti-floor conveying method for abrasives using a honeycomb floor combines the material dropping structure of the honeycomb floor with the pneumatic power of the pneumatic conveying system to realize the collection, conveying, solid-gas separation, and recycling of abrasives after sandblasting. It mainly utilizes the airflow power generated by the fan to form uniform air pressure in the air chamber under the honeycomb floor. The abrasives that fall on the honeycomb floor after sandblasting are sucked into the silo chamber through the honeycomb holes, then transported to the abrasive separation and purification system via the conveying pipeline. The clean abrasives after separation are sent back to the sandblasting main machine, and the dust is handled by the dust removal system.

advantages:

- No dead corners in abrasive recycling

- Low equipment wear and low operating costs

- Low equipment wear and low operating costs

- Low abrasive breakage rate

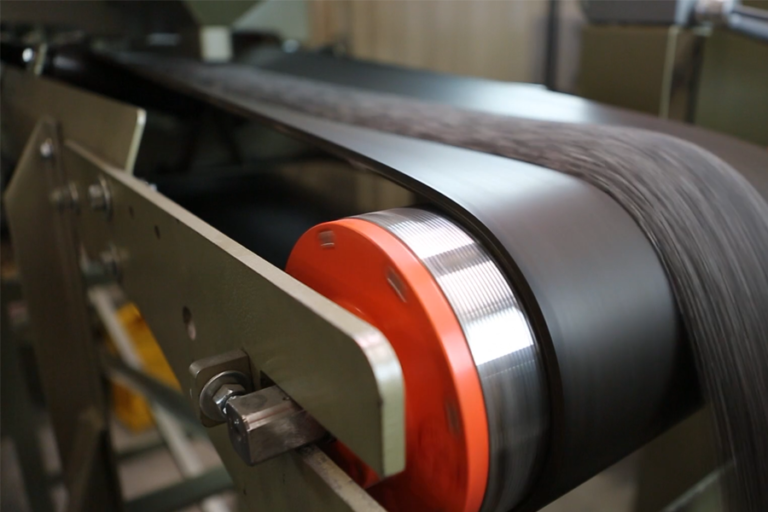

Belt conveyor recovery system

The belt-tpe abrasive transport system with adaptable performance significantly reduces the number of cycles and energy consumption, while increasing transport capacity. track conveyor with abrasive-resistant rubber. High-quality roller rails with extre- me resistance to wear and tear. Dust free covers of drives installed above the rack conveyors, inside the blasting room.

advantages:

- The cheapest solution for large cabins

- Low noise level

Summarized

There you go Now you have a good feeling about what is possible with regard to our cabin floors. Each customer has its own specific wishes or considerations. You too? Our consultants are ready to answer your questions by phone, via email or WhatsApp (button below). Or go back to the overview!