- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- disa@disachina.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

containerized blast room

Disa containerized blast rooms upgrade standard containers into fully functional blasting work environments with both durability and versatility.Its compact design endows the containerized blast room with exceptional mobility and easy installation. All it requires is the connection of compressed air and power supply to be fully operational. The installation of a fully assembled blast room can typically be completed within a single day.

Custom buildshipping container sandblasting room

Transform standard shipping containers into high-performance blasting booths with our containerized solutions—engineered for durability, versatility, and operational efficiency.

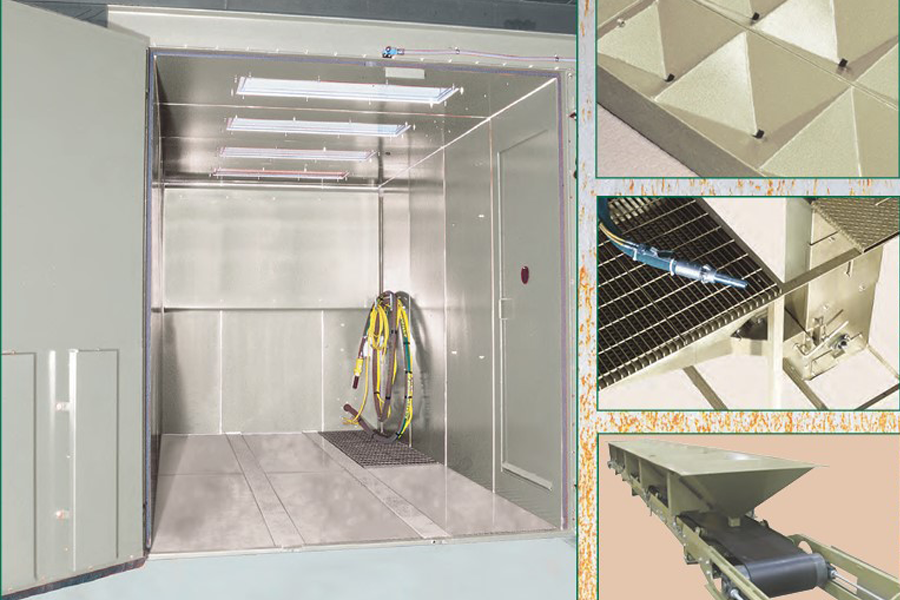

Built with a robust all-steel welded frame, each booth integrates advanced ventilation, impact-resistant rubber curtains, and purpose-built lighting to create an optimal blasting environment. Choose from a range of abrasive recovery systems—from compact bucket elevators to full-floor reclaim setups—and customize the layout, capacity, and features to match your specific workflow requirements.

Whether deployed on-site or in a fixed facility, these modular sandblasting booths deliver industrial-grade performance in a portable, space-efficient package.

This is a modular, high-performance compact blast & recovery blast container with the following features and advantages:

Space-saving design: Ideal for fitting into standard shipping containers and HI-CUBE shipping containers, and perfectly suited for limited blast workplaces.

Efficient abrasive handling: Equipped with a continuous abrasive feed system; supports standard connection to a loading hopper or floor transport of abrasive media, ensuring a smooth and uninterrupted blast & recovery process.

High-performance configuration: Built with a large-volume, highly efficient abrasive blaster; as a premium model, it is ideal for demanding industrial operations requiring high productivity and work effectiveness, and can be operated by two personnel simultaneously.

Component Overview:

A containerized blast room consists of the following components:

Blast Room Enclosure: The standard specifications of this series of blast rooms are 8 feet wide and 8 feet high, with optional lengths of 20 feet or 40 feet. Combined with customizable door design, it can not only provide a highly reliable solution for year-round indoor sandblasting operations, but also has excellent mobility, which can be flexibly relocated according to usage needs.

Abrasive Recovery System: It has a partial abrasive recovery system with a shovel-in hopper.

Abrasive Blast Pot: Equipped with safety control devices and properly interlocked with the room door.

Component bogie:Multiple configurations are available for the entry and exit of workpieces, which can be handled by conveyors, pneumatic rotary tables, or directly operated on the ground.

Room Lining Protection: Rubber lining made of wear-resistant materials provides structural protection for the enclosure.

Lighting System: Standard configuration includes LED lights with emergency lighting as a complementary feature.

Dust extractor: Depending on the type of work to be performed, the container-type sandblasting room is equipped with an exhaust system or an overpressure system. It is fitted with an abrasive recovery and screening device, as well as filters for removing dust inside the room, thereby ensuring that operators always work in a healthy environment and are protected from injury caused by abrasive blasting.

Electrical Control Panel: Controls the entire system, with in-house design and manufacturing.

For extremely heavy workpieces, the container can be equipped with loading and unloading components, screw conveyors and movable grating.

optional:

The container-type sandblasting room can be equipped with a special vibrating screen in the dynamic separator to prevent nozzle clogging and reduce maintenance work.

Example 1: custom made blast container

The containerized blast rooms offer a cost-effective and portable solution for weatherproof blasting needs. These re-engineered shipping containers are designed to deliver all the essential features of traditional blast rooms, making them ideal for both temporary and permanent blasting setups.

The design of our containerized blast rooms starts with the accurate acquisition of dimensional parameters of the workpieces to be blasted. The spatial planning of the blast room must satisfy two core requirements: it should not only accommodate workpieces of maximum specifications, but also reserve ample safe operating space for blasting operators.

Containerized blast rooms create a safe and controllable working environment for both workpieces and operators. Abrasives are fully contained within the room, enabling efficient recovery and recycling. Compared with disposable abrasive solutions, this approach helps enterprises significantly reduce production costs.

The room structure is designed to flexibly integrate a variety of abrasive recovery systems. Used abrasives can be professionally collected, screened and processed before being conveyed back to the blast pot for recycling, further improving resource utilization efficiency.

A dust collector and pipeline system of appropriate specifications not only ensures the ventilation requirements of the blast room, but also effectively enhances the visibility during operations, creating a safe and worry-free working environment for operators.

Example 2:Portable Containerized Blasting Room

Our portable containerized blasting room offers a turnkey surface preparation solution built inside a robust standard shipping container. A strategically installed partition divides the unit into two dedicated zones: Blasting Chamber – for safe and efficient abrasive blasting operations Service Room – housing all essential equipment in a compact, organized layout Once on-site, the system is operational with just compressed air and electrical power—no complex setup required. Key Features Blasting Chamber Interlocked main door prevents operation when open Personnel access door compliant with HSE and safety standards LED main lighting + emergency backup lighting Heavy-duty steel floor with side discharge and integrated screw conveyor at the partition Optimized air inlets for effective ventilation and unobstructed visibility during operation Service Room Lockable independent access door for security and maintenance Fully integrated components: Abrasive elevator Air-wash separator Pressurized blasting pot with control system Breathing-air filtration unit Dust collector Electrical control cabinet LED lighting and external silencer for reduced noise emissions Standard Models:

6m container : 4.5m long x 2.3m wide x 2.4m high blast room. Requires 7kW

9m container :6.5m long x 2.3m wide x 2.4m high blast room. Requires 7kW

12m container :9.5m long x 2.3m wide x 2.4m high blast room. Requires 8kW

Example3: Combined Containerized Shot Blasting Room Consisting of 1 x 20 foot Container + 1 x 40 foot Container

This project delivers a fully integrated sand blasting unit through the custom modification of two new shipping containers: one 40 foot unit and one 20 foot unit, built to client specifications. The detailed scope of work is outlined below.

1. 40 Foot Container Modifications

Side Panel Removal: A 20 foot section is removed from the center of the left-side corrugated panel. All cut edges are trimmed and finished.

Ventilation System: Four 1000 mm x 1000 mm horizontal openings are fabricated near the cargo doors on the right side. Louvre vents are installed to ensure optimal airflow during operation.

Door Modification: The standard double cargo doors are converted to an inward-opening configuration, fitted with safety locks for secure personnel access.

Top Reinforcement: Box-section supports are installed at 10-foot intervals along one roof edge to provide a secure mounting base for safety railings.

2. 20 Foot Container Modifications

Side Panel Removal: The entire right-side corrugated panel is removed, with all edges precision-finished.

Personnel Access: An emergency personnel door is installed at the rear of the container, located 8 feet from the end wall to allow for safe evacuation and routine access.