- View Products

- BlastWizard blast pots

- Blasting cabinets

- Injection blast cabinet SK900

- Injection blast cabinet type SKIF

- Pressure blast cabinet type Venti-Compact

- Blasting machine with rotary basket

- Turntable blasting machine

- Throughput blasting machine

- Roller conveyor blasting machine

- Internal blasting machine

- Multi-nozzle blasting machine

- Satellite table machine

- Blasting installation with sliding door

- Robotic blasting machine

- Precision spotblaster

- Custom blast cabinets

- Big blasting halls

- Shot blast container

- Shot peening installations

- Wheelblasting

- Metallisation equipment

- Blasting media

- Dust collectors

- Dehumidifiers

- Blasting with compressed air

- Suction units

- Blastwizard Blast Helmets

- References

- Blasting Knowledge

Need advice?

Need advice? Call or WhatsApp us, and you’ll get a reply within 5 minutes!

- (86)-0532-012345678

- 15112345678

- info@disamachinery.com

Get in touch

Leave your details below and one of our specialists will be in touch as soon as possible.

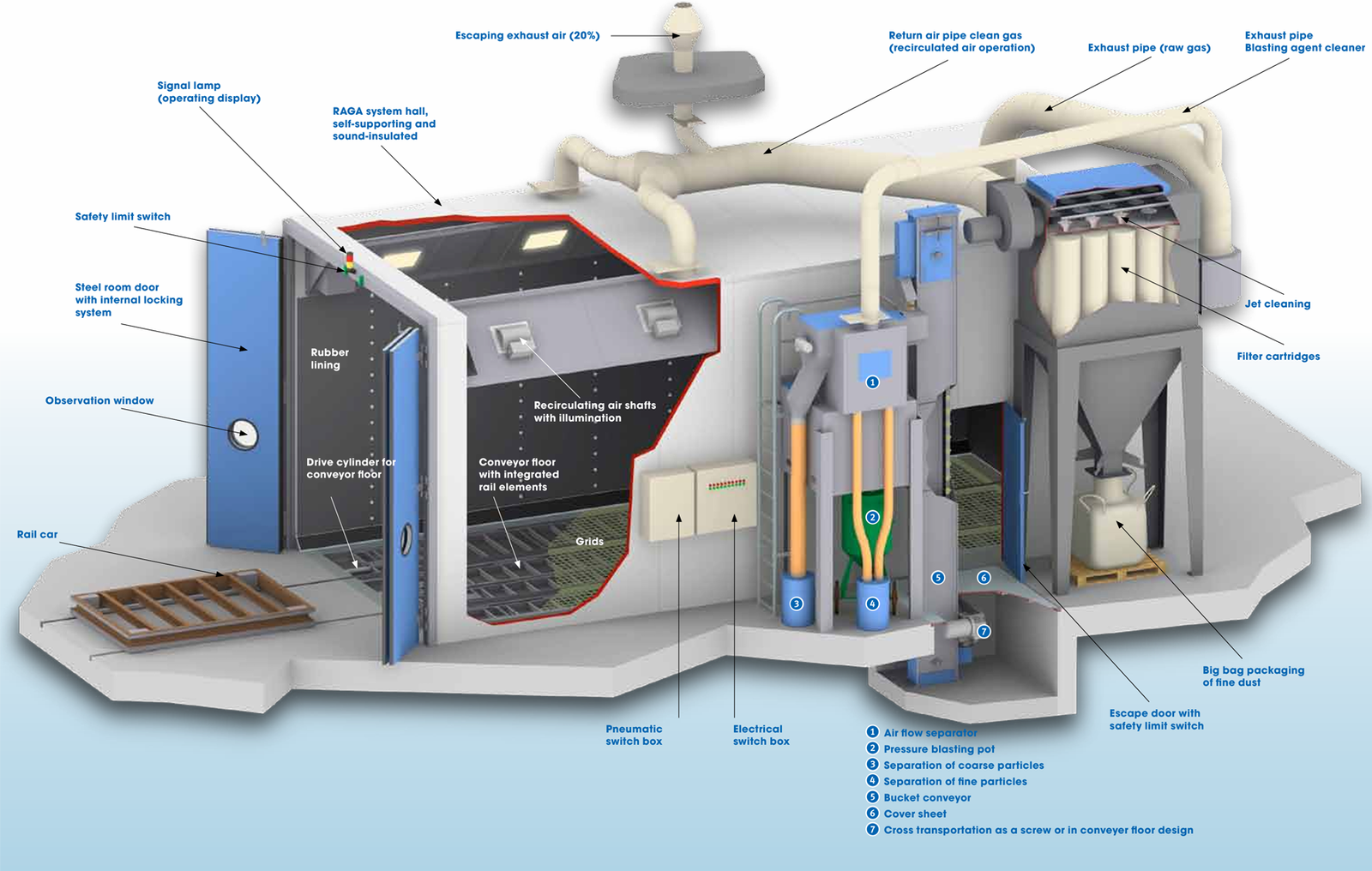

DISA MANUAL Blasting ROOM: OPTIMUM BLASTING PROCESS, INCL. SUPER CLEANING

shot blasting rooms are designed for manual or automatic compressed air shotblasting of various work pieces, such as welded pieces, castings, forgings, railway wagons, containers, etc.

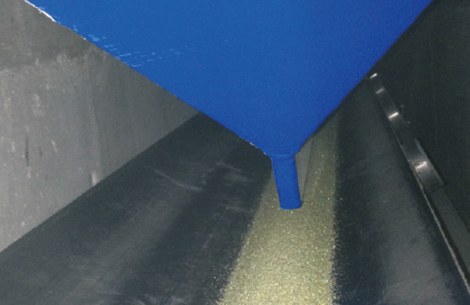

Work pieces are blasted in the chamber using compressed air that directs the blasting agent toward work pieces via a blasting nozzle. Then, a mixture of the blasting agent and residue falls into a trough, from where it is transported automatically to the elevator and air separator using scrapers and a transverse rotating worm. There, the blasting medium is purified, and after this it falls into a collection silo, ready to be used again. The shotblasting agent may be steel shot (round or granule), corundum, glass beads, etc.

Maximizing abrasive reuse boosts overall profitability: abrasive recovery cuts costs, extends blasting uptime and eliminates the time spent on manual shoveling and abrasive disposal. The system is custom-adapted to your specific abrasive type, avoiding inefficiencies and premature equipment wear common with generic systems. It is available with four professional recovery solutions—screw conveyor, scraper conveyor, pneumatic conveyor and belt conveyor—each engineered for different abrasive types and on-site construction requirements. DISA blast room recovery systems feature flexible designs, with both mechanical/pneumatic and full/floor partial floor options available to suit the factory.

- Conveyor service life more than doubled

- Ensures sustainable operation

- Up to 50% lower energy consumption

- Operating costs significantly reduced

- Polyurethane scraper: tough and durable

- Save Time and Labor

- Reduce Abrasive Costs

- Real-time monitoring of individual conveyor loads

- Pneumatic-driven maintenance-free

- direct ground mount simple infrastructure

- up-down airflow circulation high visibility

- Pneumatic-driven maintenance-free

- direct ground mount simple infrastructure

- up-down airflow circulation high visibility

- Pneumatic-driven maintenance-free

- direct ground mount simple infrastructure

- up-down airflow circulation high visibility

Fully equipped blast cabinet

View all information about some of the main components here.

Short Introduction

There are three methods for abrasive recovery in the shot blasting room: pneumatic recovery, full pit mechanical recovery, and pitless scraper recovery.

The shot blasting room equipment mainly consists of: shot blasting room body, shot blasting system, abrasive circulation system, ventilation and dust removal system, electrical control system, etc.

Structure of the sandblasting system:

Basic structure of the shot blasting system

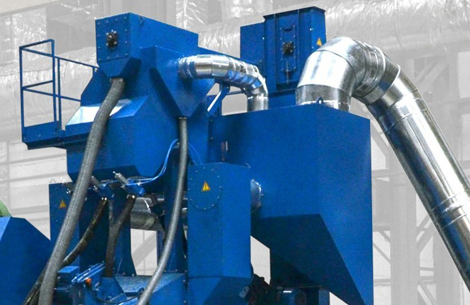

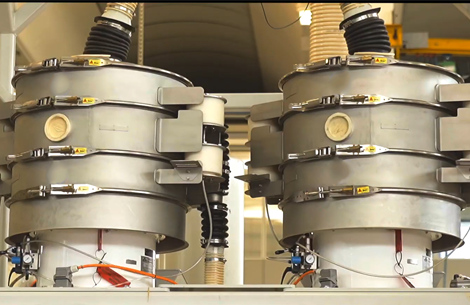

According to the process requirements, the shot blasting system adopts manual sandblasting. Special sandblasting tanks are equipped for products of different materials. The pressure and flow of the sandblasting tank can be adjusted at any time as required. Each shot blasting pot is equipped with 1-4 blast guns, and the blasting system can operate 4 spray guns simultaneously.

Dual-chamber continuous sandblaster

The lighting adopts a dust-proof lighting system, which requires that the indoor illuminance at 1m above the ground is not less than 650 lx. All doors leading to the shot blasting room are equipped with electrical interlocking devices to ensure that the sandblasting system stops working when any door is opened. A warning light is installed outside the door, and the light being on indicates that sandblasting is in progress.

Disa blasting pots, manufactured in compliance with CE standards and subjected to hydraulic testing, is operable at a pressure of 8 bar. It is fitted with an access exit for one or more operators, a remote pneumatic control device and a complete set of operator protection equipment, as well as an air filter suitable for human respiratory use.

Built in steel plate profiles and bolted one to another, they are modulated in order to satisfy any dimension in height, width and length. Inside (except on the ceiling) there is a rubber coating that protects them against abrasion and helps in the acoustic insulation.

These particular systems consist of modular steel or self-supporting panels with polyurethane resin insulation. The inner walls are lined with special anti-abrasive rubber.

The floor is made of metal grating, under which the automatic abrasive recovery system is placed.

Rubber blast room roll up doors are a space saving alternative to swing doors. The doors provide a seal for the abrasive blast room as well as insulating and reducing the noise levels of the blasting operation.

The service door is built in welded profiles and has a closing in steel plates, and is internally coated with abrasion resistant rubber.

Sophisticated construction, high-quality materials, monitoring of conveyor-belt rail- ing and tensioning, which results in reduced wear and tear and prevention of slip- page or damage.

Each one features four 40W fluorescent lamps. Their construction and positioning enable maximum utilization of the luminosity. The fastening system allows easy removal, for maintenance.

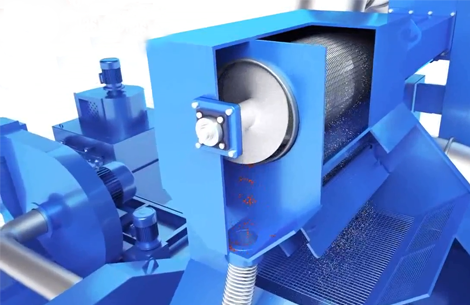

Adaptable abrasive separation intensity and selective use of the vibration sieve with automatic mode for self-cleaning separates the abrasive precisely, increasing the reliability of the separator and facilitating its maintenance.

Abrasives that are too large in size are discharged into the waste bin, and particles that are too small are sent to the dust collector.

A special Vibration sieve unit with standard size mashes for media clasification, additionally supported by a magnetic filter, is installed for a good media separation.

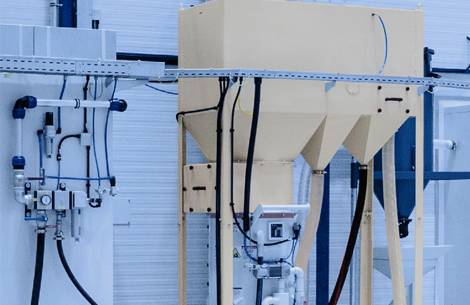

Reusable abrasives enter the vibrating oversized debris screen from the cyclone separator to remove any large particles or debris. Then, the reusable abrasives fall into the hopper, ready to be used again.

Recycling and abrasive consumption are matched. However, a buffer vessel is always necessary to absorb fluctuations.

Mounted on a shielded cabinet, it has thermal protection and interlocking for the motors, which makes it impossible to connect them in the incorrect order. Optionally, it is supplied with a PLC for the automatic control of the equipment.

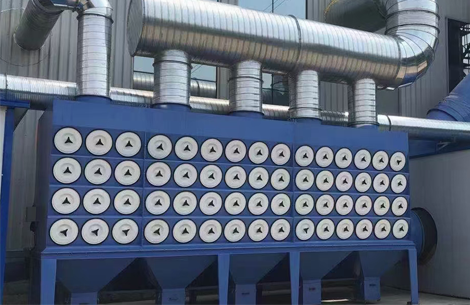

Of course, a lot of dust is created during blasting. Our heavy duty filters are extremely cost effective and are optimized for short maintenance intervals.

The large walk-in blast cabinet

We often build and install the large blast cabinet for contract blasting companies, for manufacturers of our own product or for suppliers in large machine construction. Think of blasting cabinets for the preservation of large or many different constructions. Blast cabinets are also ideal for the glass beading of all kinds of stainless steel products and constructions. The most eye-catching part is the sandwich panel casing of the blast cabinet. The pipework of the dust extraction is often also clearly visible. A normal size blast cabinet is 4 meters wide, 4 meters high and 8 meters deep. The price of the smallest “walk-in” blast cabinet starts at around 40,000 Euro and goes as high as one million Euro. Look here for the largest blasting cabinets we have ever made.

Blast cabinet: the principle

This is the place where you can learn how a blast cabinet works and how the abrasive makes its way through the machine. First of all, blasting media is thrown from the bags into the silo. It ends up directly in the pressure blasting pot, after which it is pressurized. After opening the tap, the abrasive is mixed with compressed air and flies at high speed through the hose and onto the product. This is where the blast cabinet and its components prove their worth.

During blasting, the abrasive falls to the ground through the grids and into the cabin floor, where the floor transport system ensures that it reaches the elevator. From there, the abrasive is raised into trays and poured into the silo, after it has been separated from dust in the cleaner. From there, the filtered agent is fed back into the blasting cabinet.

The Straaltechniek blasting cabinet: keys & economics

The blast cabinet design is based on economy and technology. We quantify a number of things. A few examples:

- First of all, with the blast cabinets of Straaltechniek, you are assured of access to the very best blasting medium. It’s about 10% more expensive than the competitor’s. But it gives a much better roughness, much better productivity (shines up to 100% faster and lasts up to 3 times longer), which saves you money. We can prove this to you with jet tests. These blast tests are done by them because they blast 240,000 square feet per year!

- We can then quantify for you where you save money with our blast cabinet. This is primarily the case with our blasting boilers, which have higher pressures and thus higher productivity with the same compressed air consumption. Subsequently, our filter is many times more robust and the fan curve is optimized by us for your specific situation. We can do this, unlike other blast cabinet suppliers. With the blast cabinet floor, the “cost of ownership” is very much taken into account. With our compressed air system we supply a solution that is cheaper for you (in purchase but also in operation) than suppliers with electrically driven scrapers. Finally, we have enormous experience and knowledge in the field of in-service cleaning of the filter cartridges in the filter installation of the blast cabinet. We give the necessary attention to the setting of this cleaning, so that you have to pay the bill for unnecessarily high compressed air consumption.

- The air flow in the blast cabinet determines the employee’s working comfort. The extraction consists of inlet grilles, baffle plates, extraction points. The filter is placed outside, but often against the blast cabinet. The blasting process, the abrasive, the size of the blast cabinet and the properties of the product determine the refresh rate of the air. To calculate this, we divide the capacity (m3 / h) of the filter by the content of the blast cabinet (m3). Of course, the parameters mentioned also influence the cloth surface in the filter. You may also have a maximum permitted emission of dust from blast cabinet extraction in mind for the environmental permit. Or perhaps you would like the air technology to be designed in such a way that the filtered air from the blast cabinet is returned to the production hall. Our partner www.naaykens.com is highly competent in the field of blast cabinet extraction. Naaykens can achieve unprecedented filtration efficiency. Demonstrable in delivered projects. Which You can visit as a reference visit. Have a look at filters or at www.naaykens.com. There, you will find a lot of information about extraction from a blast cabinet.

- The blasting method has a lot of influence on the components in the blast cabinet. Metallizing is of course a completely different process than shot blasting. Every part of the blast cabinet is affected by this. The filter may have to be constructed in accordance with ATEX guidelines.

- Maybe you want to both metalize and blast in your blast cabinet! We can do this! We have solutions for this and this is often requested in the market.

- Would you like to purchase a spraying and blasting booth at the same time? We are happy to advise you about the possibilities and can manage the entire project to unburden you!